OVEN AND ROBOTIC APPLICATIONS

INK CURING

Designed for high performance and reliability, this drying furnace offers advanced features across process control, safety and energy efficiency

Process control

· Fully automated temperature control system for consistent thermal processing

· Automatically regulated air inlet to ensure reliable air exchange and uniform conditions

Safety features

· Complaint with EN 1539 safety standards for processing solvent-based materials

· Robust construction designed for continuous heavy-duty operation

· Over temperature limiter with manual reset, meeting thermal protection class 2 requirements in accordance with EN 60519-2

Efficiency enhancements

· High air exchange rate to support rapid drying cycles

· High grade insulation ensures external surface temperatures to remain below 20ºC above room temperature

· Furnace commissioning includes temperature uniformity testing to optimise process performance

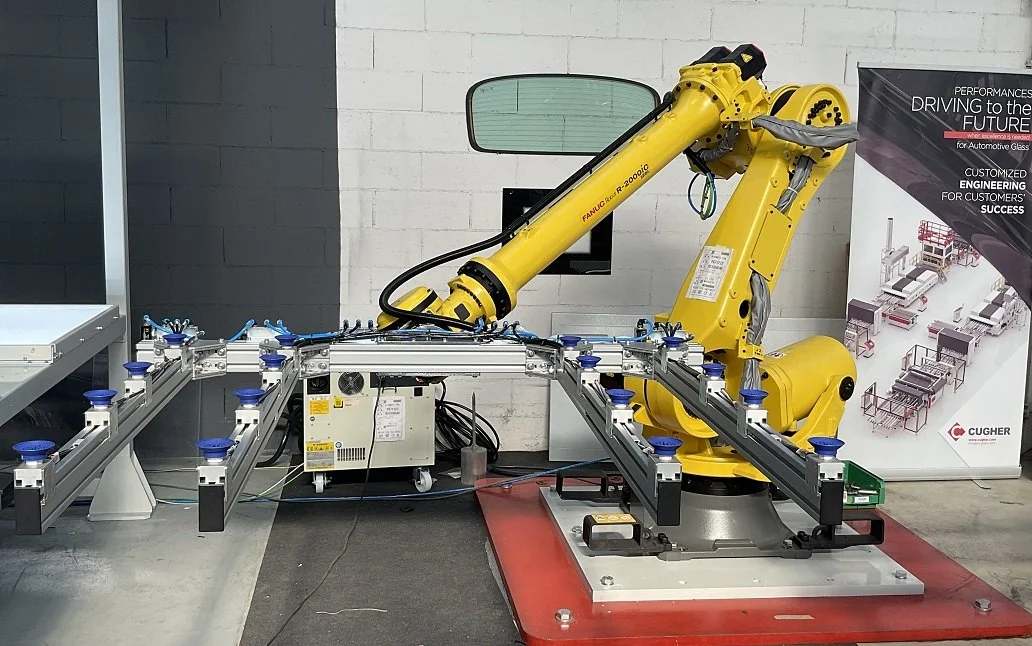

ROBOTIC APPLICATIONS

Cugher’s robotic applications, essential in modern industry and true allies of human, allow for the optimisation of the production line

· The quality of the process improves because operations are faster, more precise and uniform

· Labor costs decrease compared to manual activities

· Risks for complex and dangerous operations are reduced

· The quality of the operators works increases as they become supervisors rather than mere executors of repetitive tasks.

Cugher offers two advanced automation solutions:

Robotic Islands: automated workspaces with robot manipulators for loading, unloading and palletising. Boosting productivity and easily reconfigurable for different processes.

Robotics with vision systems: Robots integrated with vision technology for real time adjustments and precise positioning, ensuring consistent quality in complex handling tasks.