LASER MACHINES

Applyca builds its own tailor-made fiber optic laser machines, especially designed for processes that require continuous position inversions, for example, in the construction of the teeth for circular saw blades.

However, thanks to their transversal expertise in the field of industrial automation, Applyca also use lasers for functions that go beyond cutting, welding, marking. For example, cleaning rust or paint large surfaces.

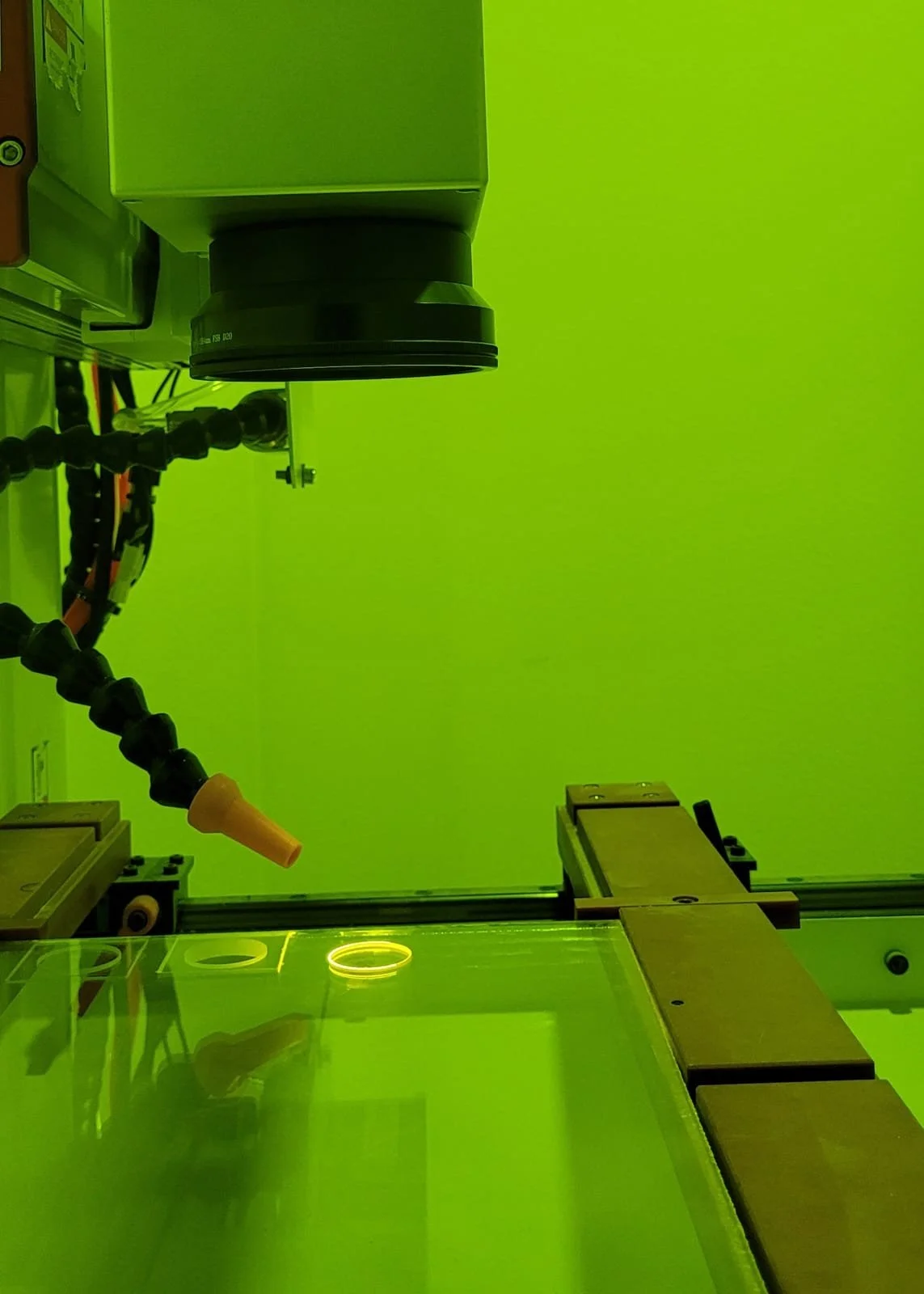

GLASS CUTTING AND DRILLING

With Applycas latest laser technology, precision cuts and holes can be produced without mechanical tools or water systems. The result is faster, cleaner, and more cost-effective glass processing.

The laser head, mounted on high-precision Cartesian axes, moves freely across the work surface, reaching any point with unmatched accuracy and repeatability.

ADVANTAGE OF LASER CUTTING

· Perform a highly efficient, fast and precise cut to obtain a finished product or ready for subsequent processing (welding, bending …)

· Are interfaced with the design and the rest of the production

· Can send information to auto-correct their programs

· Are reliable thanks to high quality components

· Have compact dimensions to fit into confined spaces

· Are ready for use, once delivered

Key Benefits :

· No tool wear or replacement costs

· No water or coolants required

· Faster operating speeds

· Clean, contact-free processing

· Seamless CAD/CAM integration

VENETHIA 3015

Applyca proposes VENETHIA 3015.

New design and high precision, VENETHIA 3015 is a fiber laser cutting machine equipped with a 4KW source and a 3000×1500 mm working range.

With double independent loading/unloading pallets making it readily available for automatic loading with robot assistance.

RoboLaser STEflex

All-in-one multifunctional laser

Applyca’s latest innovation: RoboLaser STEflex, an extremely compact and versatile laser cutting machine capable of performing a variety of industrial operations: metal sheet laser cutting, threading, tapping and tube laser cutting, all in one automatic setup.

ROBO LASER CUBE

A model to be customised as desired

It’s a compact fibre laser cutting machine, powered by Fanuc control and robotics for guaranteed quality and worldwide support.

With a 1500 × 1500 mm working area, it fits easily into small spaces. The automated table kicks off new cutting phases in under 5 seconds and can juggle multiple orders on the same sheet. Thanks to its smart CAD/CAM, pieces are recognized, picked up by a versatile robot gripper, and arranged with precision. Add in linear magnetic motors, and you get speed, H7-level accuracy, and low maintenance.