MISTRELLO

For many years, Officine Mistrello has been a specialist in the design and manufacture of technologically advanced storage and handling systems for all types of architectural stone panels including natural stone, granite, quartz, and ceramic.

Renowned for their versatility and customisation, Mistrello systems can be installed in stone workshops of any size. Each solution is fully tailored to meet specific customer requirements, ensuring optimal integration and performance.

With decades of experience, Mistrello develops innovative systems for warehouse storage, sorting, loading, and unloading, all designed to ensure maximum productivity, flexibility, and operator safety.

COMPACT STORAGE STAND-ALONE SOLUTIONS

The concertina racking systems produced by Mistrello have been specifically designed for storage. These machines exploit all available space thanks to the motorised concertina closure. They are extremely user-friendly and loading (storage) and unloading (picking) can be done quickly and SAFELY without risk of error. Each machine is powered by a motor (0.75 kW) and a gear reducer.

Mistrello’s range of concertina racking systems can be infinitely tailored to exactly match each specific requirement of customisation.

Each rack moves along a pair of special “H profile” rails through 4 wheels per strut (for a total of 8), which are made of S355 steel and are equipped with 12 ball bearings.

Each rack is supplied with protective guards over the wheels.

COMPACT OUTDOOR VERSION

TRIPLE SEMI-AUTOMATIC STORAGE

100 ELEMENTS/SLOTS

CAPACITY 420 tons

1748SLABS (12mm)

1027 SLABS (20mm)

629 SLABS (30mm)

OCCUPIED SPACE 133 m2

AUTOMATIC HANDLING SOLUTION

This completely customised system allows the following advantages/operations:

• Rationalisation of space thanks to compact warehouses

• Quality control, picture and labelling

• Safety conditions for the operators

• Automatic handling of slabs of any size

• Complete Software integration by the Mistrello

Stock Management

•Preparation of the next day production (pre-buffer area);

•Possibility to show slabs to customers;

• Vertical and/or horizontal exits.

MOVING

SLABS OMEGA FLIP SYSTEM

The compact racking systems are prepared to be equipped with (OPTIONAL) the slabs OMEGA flip system. This option includes the

supply of 2 OMEGA rails correctly sized, 4 removable tubes/supports and 2 special sensors that prevent the operation in case the sup-

ports are inside the machine.

These supports, whose structure is sized according to the load they have to support, allows the operator to move the slabs in order to

pick up the underlying slabs.

SEMI-AUTOMATIC STORAGE

16 ELEMENTS/SLOTS

CAPACITY 104 tons

417 SLABS (12mm)

248 SLABS (20mm)

161 SLABS (30mm)

OCCUPIED SPACE 31,4 m2

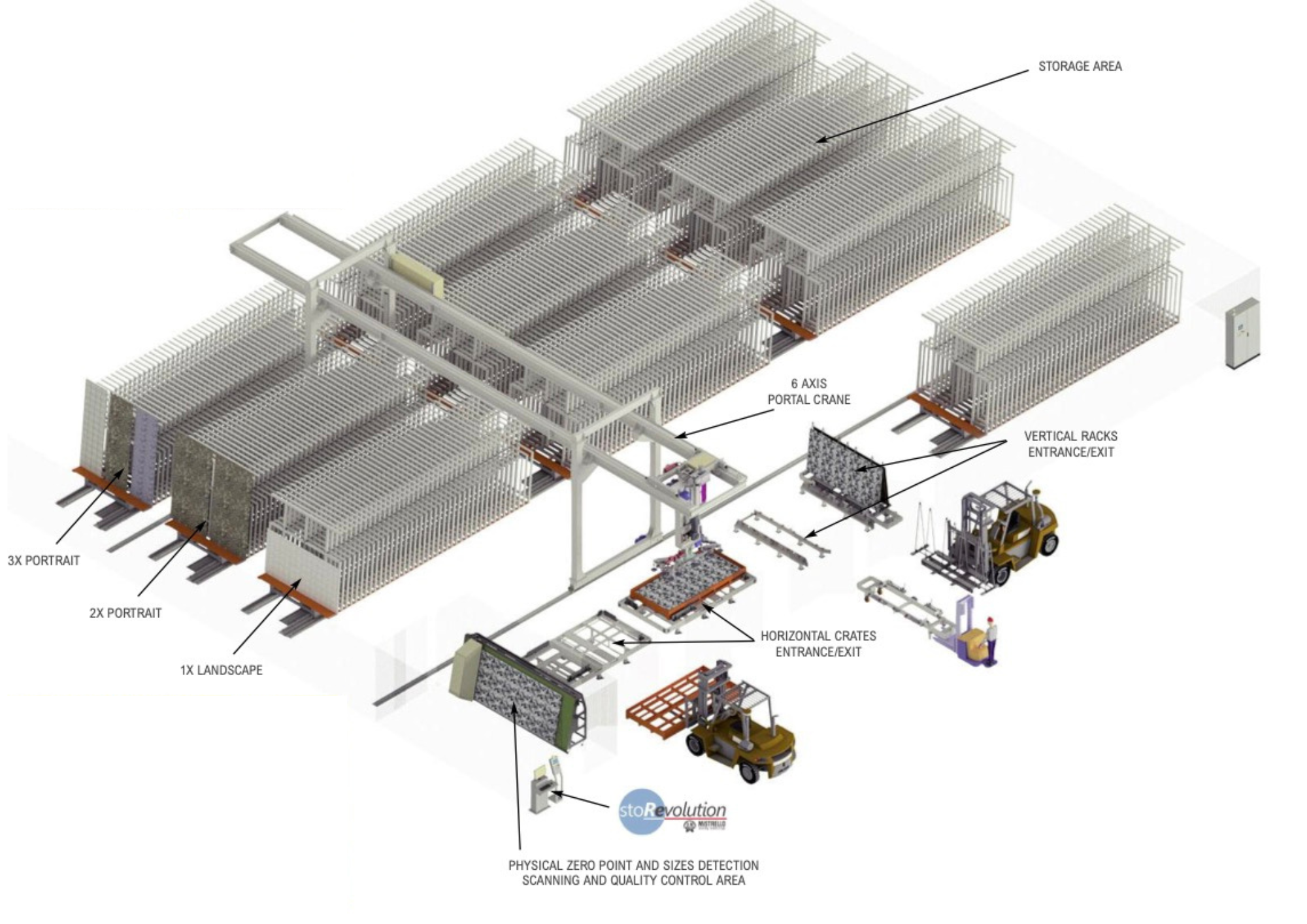

PREDATOR 6 AXIS PORTAL CRANE

STORAGE AREA: OCCUPIED SPACE 192 m2

164 ELEMENTS/RACKS FOR A POTENTIAL STORAGE OF

492 POSITIONS (3X PORTRAIT) OR

328 POSITIONS (2X PORTRAIT)

SLABS CAPACITY 3X PORTRAIT

- 5412 SLABS (12mm AVERAGE THICKNESS)

SLABS CAPACITY 2X PORTRAIT

- 3608 SLABS (12mm AVERAGE THICKNESS) or

- 1968 (20mm AVERAGE THICKNESS) or

- 1312 (30mm AVERAGE THICKNESS)

CRANE MAX HANDLING CAPACITY: 800 kg

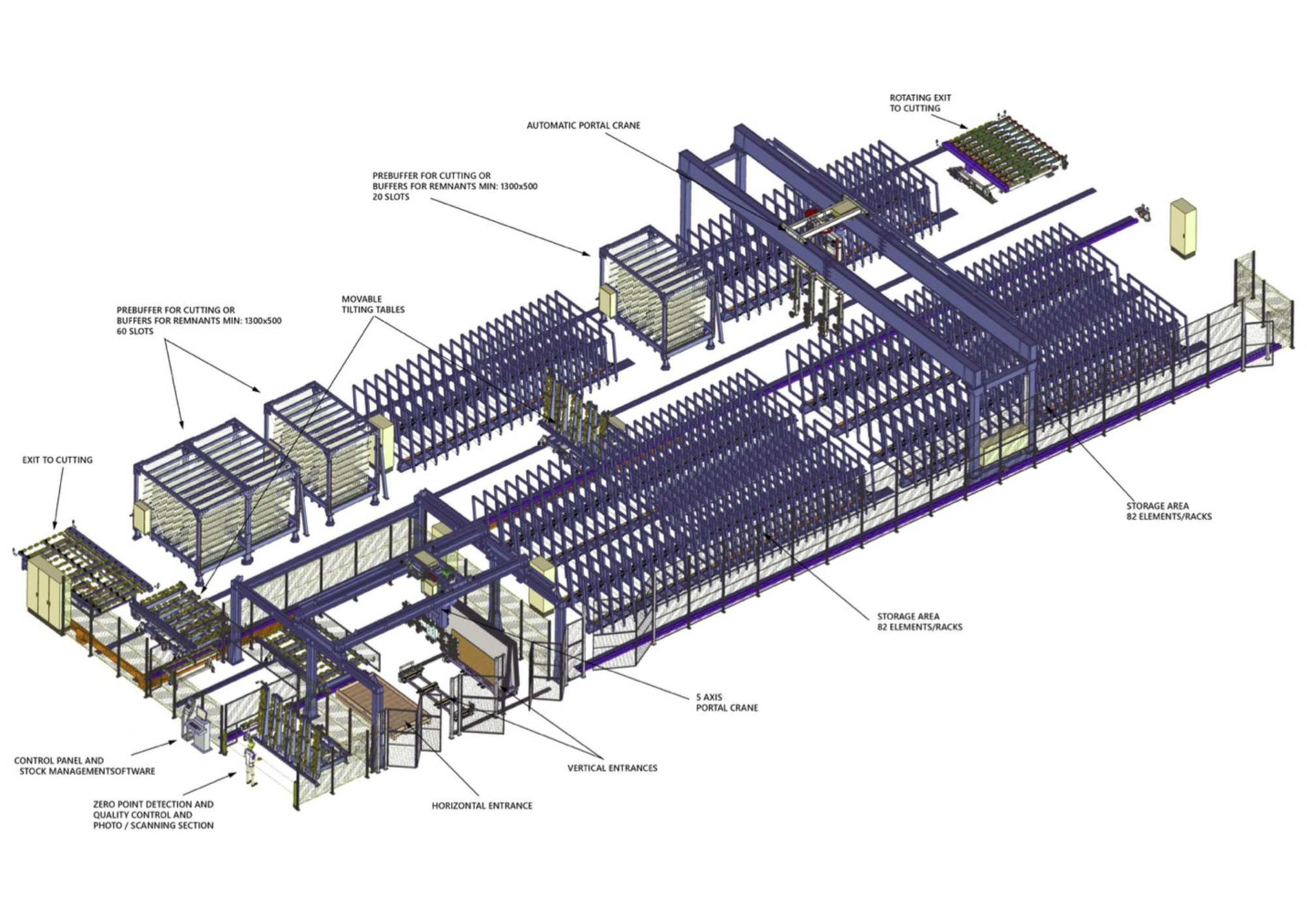

AUTOMATIC HANDLING SYSTEMS

164 ELEMENTS/RACKS FOR A POTENTIAL STORAGE OF

- 5412 SLABS (12mm AVERAGE THICKNESS)

SLABS CAPACITY

- 4602 SLABS (12mm AVERAGE THICKNESS) or

- 2666 (20mm AVERAGE THICKNESS) or

- 1772 (30mm AVERAGE THICKNESS

ULTRAMATIC 5000 HANDLING SYSTEM OVERVIEW

1 -AUTOMATIC ROTATING A-FRAME

Automatic rotating A-frame (25+25 tons); it allows the slab loading without stopping the

plant automatic cycle.

2 -TELESCOPIC LOADER (PATENTED)

Telescopic loader to pick slabs up (polished side or rough side). Able to move slabs with

the polished side up.

3- Quality Control Area

Automatic tilting table with HD camera. Quality control area protected by safety sensors. Software connection with the stock management.

4 - AUTOMATIC GANTRY CRANE SYSTEM

24 mt. span/gauge running under the manual cranes. Capacity: 800 kg. single slab. Patented system to place slabs without damaging them. Rotation 270°. Min slab size (w)1250mm x (h)950mm.

5- storage area

12X automatic concertina racking systems. Total capacity 5080 slabs (20mm). 452 different positions/products.

6-Restore

Automatic buffer/Restore system composed of 60 slots. Each slot can host up to 5 rem

nants in-line. Minimum dimension of remnant (w) 1300mm x (h) 500mm. Pieces managed

automatically by the tilting table

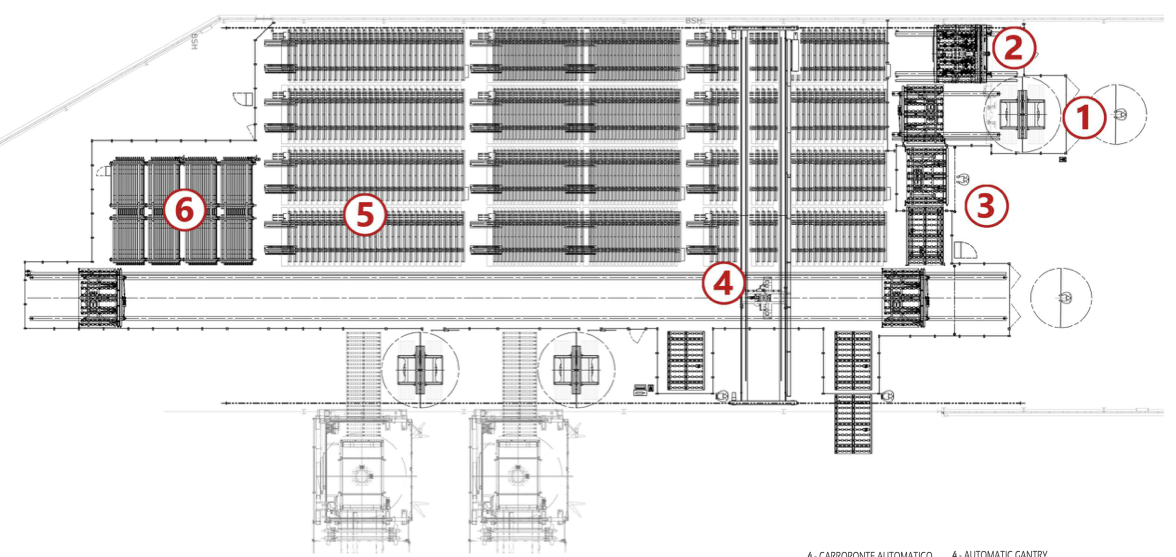

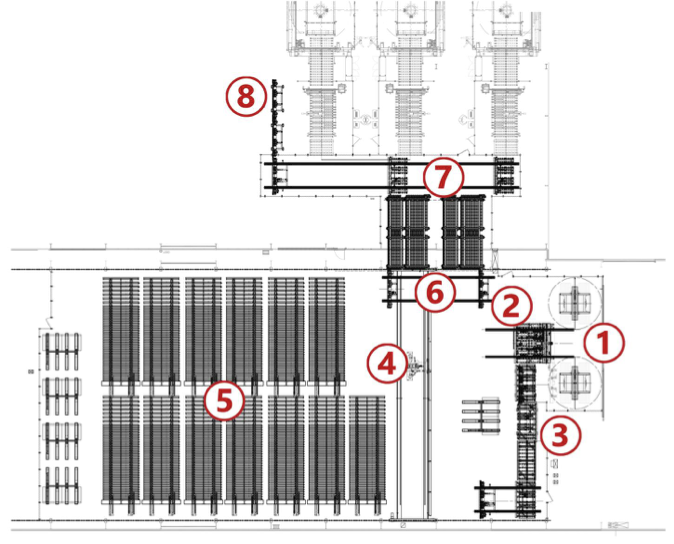

SUPERFLOW 5000 HANDLING SYSTEM

1 - AUTOMATIC ROTATING A-FRAME

Automatic rotating A-frame (30+30 tons); temporary storage system to shift the entire load inside.

2 - TELESCOPIC LOADER (PATENTED)

Telescopic loader and horizontal conveyors to run slabs horizontally and vertically along the handling line.

3 - SOFTWARE STOREVOLUTION

Complete stock management software system that offers the user the possibility of knowing the exact position of each slab and, in general, all the characteristics of the slabs contained in the warehouse

4 - AUTOMATIC BRIDGE AERIAL SELECTOR

24 metre span running below the manual bridge crane. The selector is equipped with a floor mounted loader with suction cups to manage each movement, such as picking, deposit, rotation and so on.

5 - STORAGE AREA

13x automatic storage systems (double version). 450 positions in total which can store more than 5000 slabs (20mm thickness).

6 - QUALITY CONTROL AREA

Automatic vertical conveyor to feed 50 double positions (100 slots) with slabs for the daily production. This buffer has been placed between two different bays in order to shift the material from one bay to the other without any lifting operation.

7 - TILTING TABLE TO FEED THREE LINES

The automatic tilting table, in the opposite bay, retrieves slabs to feed saws and waterjets.

8 - VERTICAL CONVEYOR TO PUT REMNANTS BACK

After cutting, the operator can easily send remnants back to the warehouse (buffer) by means of this automatic vertical conveyor.