All Cugher dryers comply with the highest energy standards and are designed as an integral part of the line, with the possibility to study and realise different temperature curves in each module, to ensure an improved productivity.

IR DRYERS

Cugher’s IR Dryer combines infrared lamps and air blades to ensure the uniform heat distribution for faster, more effective ink curing. Conveyor speed is adjustable to meet specific productivity goals. Energy saving features allow lamp power to be tailored to each glass type, minimising unnecessary consumption. Power setting can be stored and recalled via the operator panel. Glass is safely transported using Kevlar belts, while a controlled air circulation system in the cold module the glass to approximately 30º above ambient temperature.

UV DRYERS

Cugher Digital UV Dryers are equipped with dedicated anti-reflection shields at both the inlet and outlet, ensuring operator safety by protecting against UV radiation. An advanced digital lamp control system enhances energy efficiency and boosts overall productivity.

IR/UV COMBI DRYERS

Cugher combi dryers consist of three sections: an IR dryer with hot modules, a UV dryer and an IR dryer with cold modules (cooling section).

When the UV drying function is active, the first and third sections operate as conveyors. Conversely, when the IR drying is in use, the UV section functions as a conveyor. This flexible configuration ensures efficient handling and optimal drying performances across different production needs.

BUILDING & INTERIOR DESIGN

SKETCH SERIES

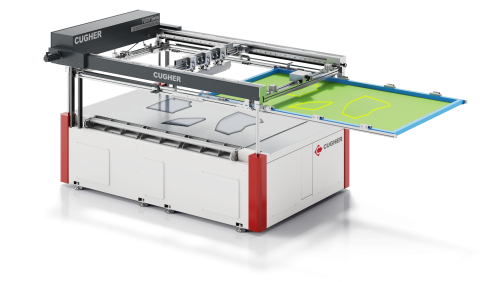

The machine supports rectangular glass sizes from 600x500mm to 2700x1600mm, with an adjustable frame referenced on the left front side. A movable screen enables customised printing on various glass areas. Fully standalone, it is also ready for seamless inline integration.

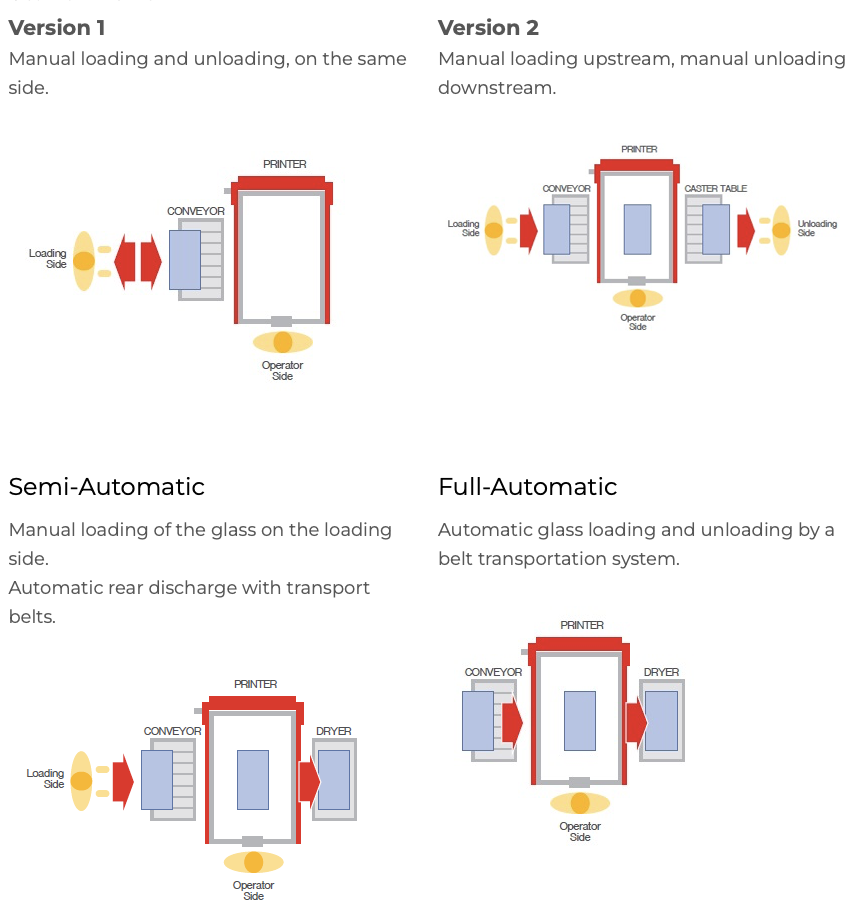

HARPS SYSTEM

The Automated Harps Rack System is an efficient glass handling solution designed for small to medium glassworks, facilitating loading and unloading of glass sheets on vertical production lines for dimensions up to 3000 x 1500mm. After cutting, operators place glass sheets onto harps in production order, each holding up to 40 sheets. The harp is then loaded onto a modular ground structure that raises and moved it forward, automatically unloading sheets one by one. Once empty, the harp is returned for reloading while other harps continue the process. This system can also operate in reverse for unloading.

CUGHER

PRINT SERIES

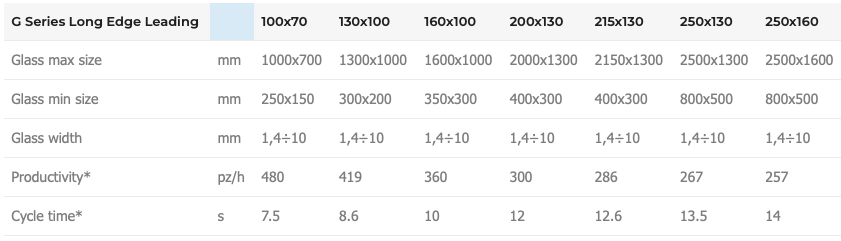

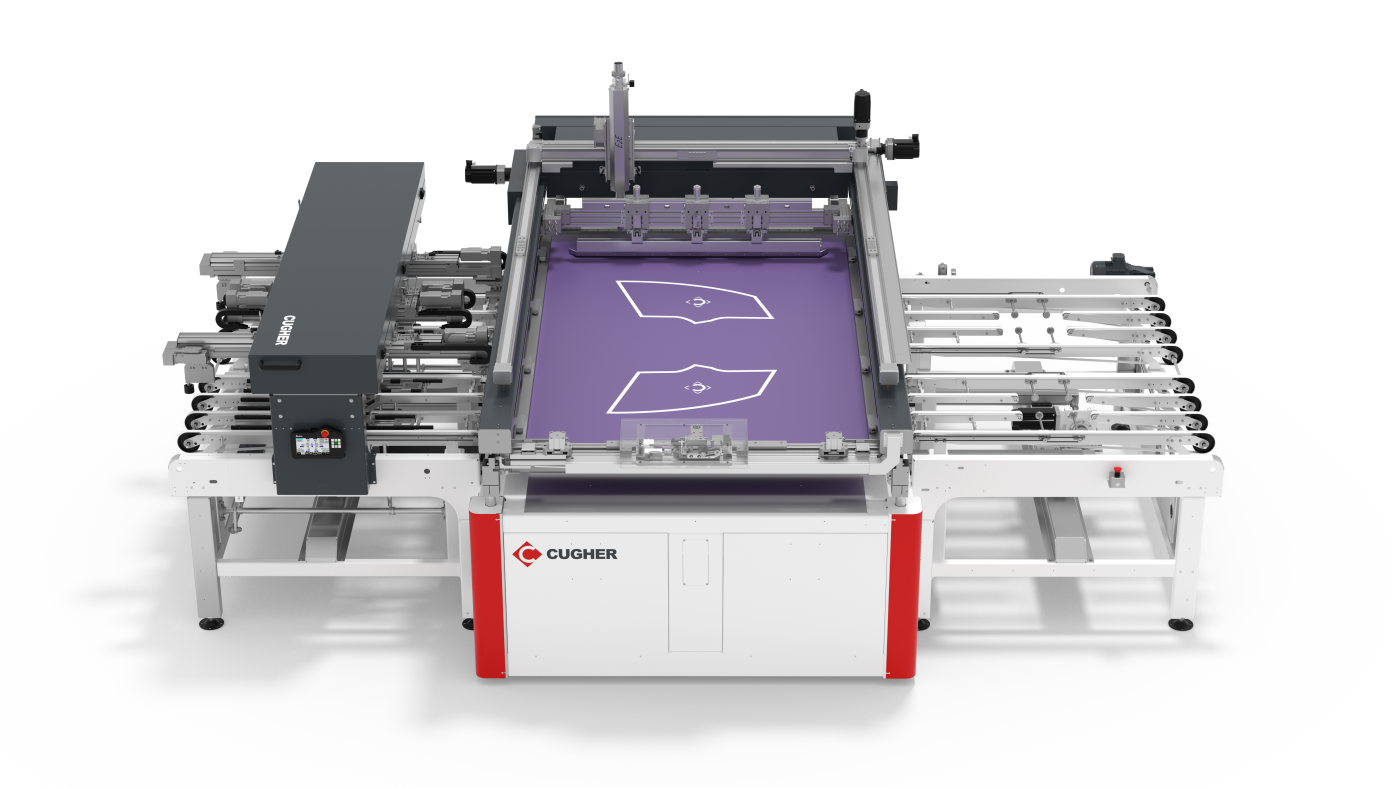

G SERIES

The G Series printing machines use a shuttle system with two independent cross-shaped holders and off-table centring to transport glass. This design maximises printing speed for small to medium sized glass. Each holder features a vacuum cup system, allowing the walking beam to collect the glass directly from the inlet conveyors centring device. This ensures precise transport and eliminates the need for additional alignment before printing.

DOUBLE GLASSES SERIES

The G series DLE (Double Lite Edition) has been engineered to provide maximum flexibility within a single printing line. It allows for the simultaneous printing of two small glass panels (such as sidelights or vents) or a single large panel (such as backlite, windshield or sunroof) on one machine.

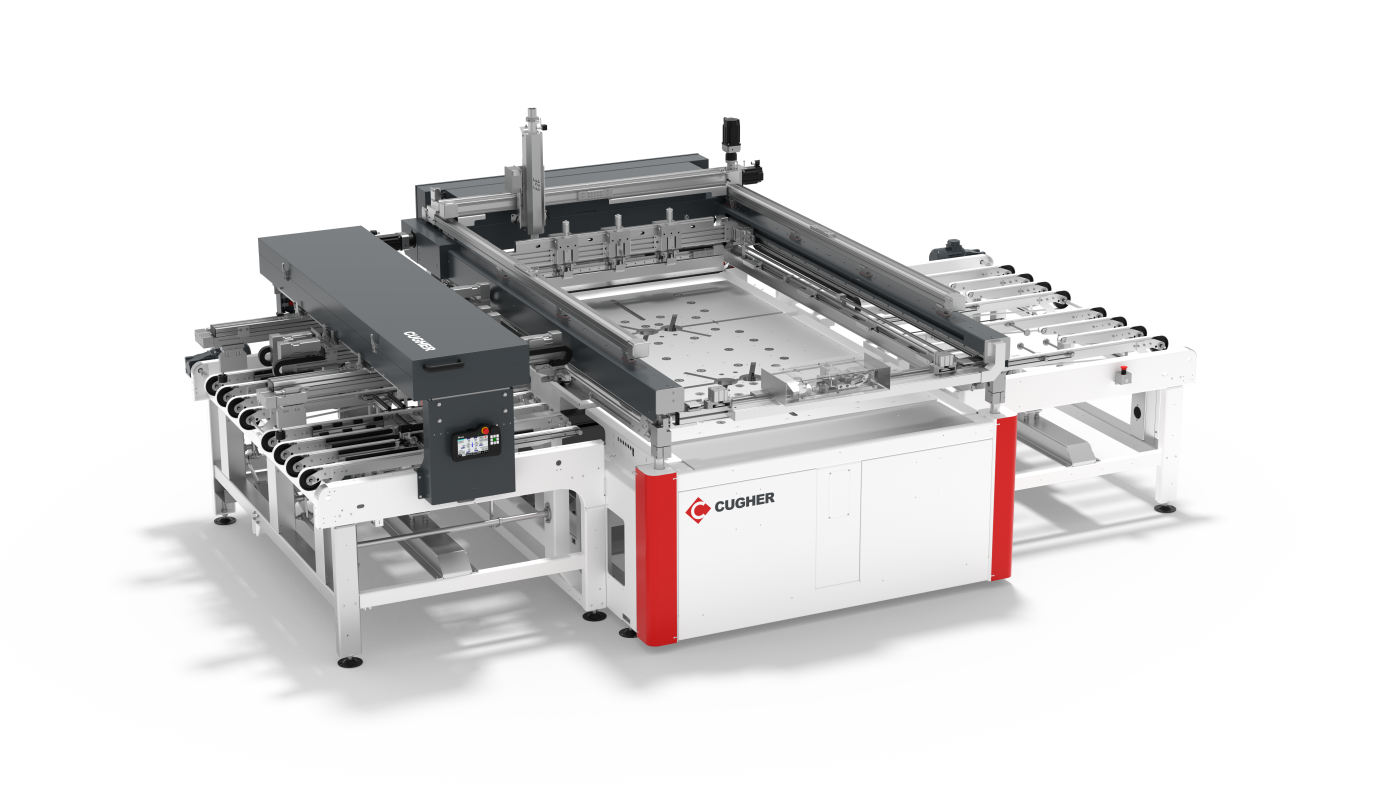

J SERIES

The Series J automatic silk Screen Printing Machine consists of an entry/pre-alignment conveyor, the main printing unit and a synchronized exit conveyor. Its robust construction features a specially treated aluminium printing table and an integrated belt transport system with auto- centring capability. Built using high quality, high-efficiency components, the Series J requires minimal land simplified maintenance.

LOGO PRINT STATION

The Logo Print Station is a specialised system comprising a booking conveyor and a logo printing unit that work together to accurately centre and print logos on the underside of the glass. Movement is driven by a pneumatic linear guide. The squeegee and flood bar speeds can be adjusted independently, while their vertical motion is controlled by dedicated cylinders. The station operated with its own integrated PLC for precise and reliable performance.

FLEXY SERIES

Designed for total flexibility, this system is ideal for printing on various glass types and is perfectly suited for small and mixed production lots. It features a stainless-steel magnetic table with micro holes, equipped with a vacuum and blow system to ensure easy and precise glass nesting. Manual loading and unloading are performed from the operator side, supporting glass dimensions up to 1300x2000mm, with a minimum printing size of 2000x200mm. All functions are managed by programmable logic controller (PLC), ensuring reliable operation, while the systems design allows for easy and safe maintenance.

HANDLING PRODUCTS

The high range of Cugher handling products allows transportation and stacking of glasses with any dimension and shape in all the directions inside production plant

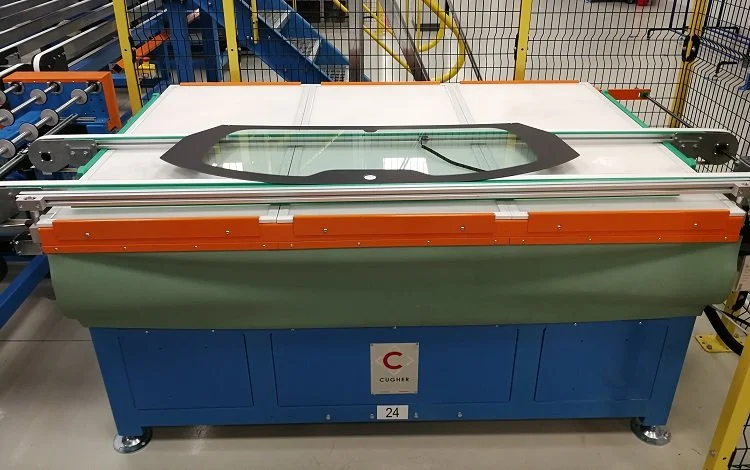

BELT CONVEYOR

Belt conveyors are composed of belts driven by pulleys connected to a shaft, ensuring movement aligned with the direction of glass flow. The structure is constructed from steel profiles and finished with a powder coating to prevent oxidation of the metal components.

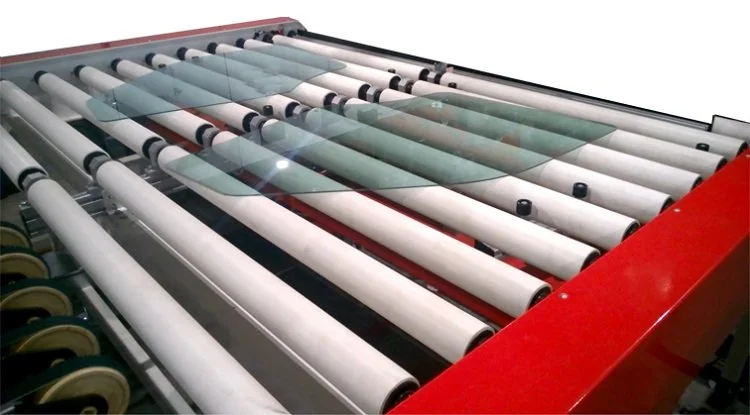

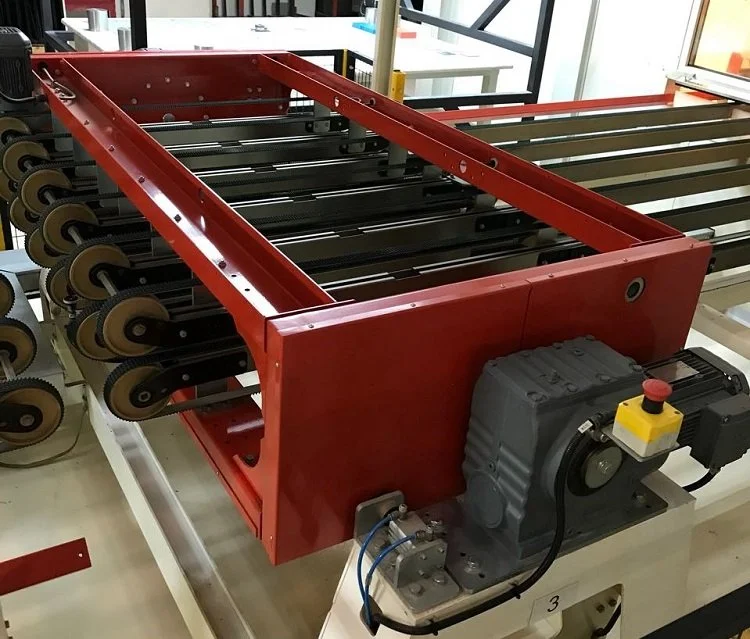

ROLLER CONVEYOR

Special conveyors equipped with ground rollers are driven by an alternating current motor. The weld free design ensures exceptional structural stability and facilitates easy maintenance.

TILTING BRIDGE

Upon request, the conveyor can be equipped with a tilting screen, enabling the controlled passage of personnel and/or materials through the glass handling line.

LOADING/UNLOADING CONVEYOR

The loading and unloading of the glass take place thanks to a conveyor equipped with forks which, starting from a vertical position are lowered until the glass is deposited on the transport rollers.

CORNER CONVEYOR

A combination of roller and belts, with the belts aligned to the direction of glass flow and the rollers providing optimal support for the perpendicular transfer of glass.

STACKER

The stacker is designed to stack glasses, equipped with motors that activate the roller conveyor and with a chain for lifting the glass. When used as a conveyor, it is able to work following the speed of the line.

VERTICAL INSPECTION STATION

The automatic glass sandblasting series the ZEPHIR represents an excellent compromise between quality and price. It’s a solid and compact equipment very easily usable by every operator, which provides high productivity despite the very low electrical and compressed-air consumption. The Zephir offers several working options, it’s possible to operate in automatic or manual mode and the maximum working height can be doubled being the cabin open topped.

FLAT INSPECTION STATION

The inspection conveyor features a specialised enclosure located beneath the belts for print quality verification. It can also be equipped with a handling system that allows it to be positioned vertically for enhanced inspection capabilities.

ROTATING TABLE

The belt conveyor enables glass rotation via integrated vacuum cup system. The operator can select and confirm a +90 or -90º rotation through the control panel interface.

LIFT CONVEYOR

Belt conveyor that has the capability to lift the glass from a lower height to a higher one.

FLIPPING OVER

Double belt conveyor that rotates to flip over the glasses

PAIRING STATION WITH ROTATION

Centring table with glass lifting system to pair the glasses. It allows to overturn the glass too.

WASHER BUFFER

Maximum five positions stacker to empty the washer.

CULLET BIN

Removable cullet able to receive the discarded glasses, it can be lifted by forklifts on either side.

TURNING POT

Machinery to amalgamate the inks before the use.

SQUEEGEE SHARPENER

Machinery that allows to sharpen the squeegee.

HOME APPLIANCE SERIES

FAST SERIES PRINTING MACHINE

· Possibility to set different speeds for squeegee bar and scraper

· Anti-drip system, on the printing bridge (squeegee bar / scraper group)

· Constant pressure of squeegee bar and scraper, which can be set from the recipe on the operator panel

· Quick and easy frame registration, with micrometric precision on all directions, including rotation

· Adjustable height of printing head, depending on glass thickness and to make cleaning and maintenance operations easier

· Frame extraction without losing the registers and pneumatic locking of the same.

· Possibility to raise the printing head up to 500 mm to facilitate cleaning / maintenance operations (in total 1500 mm from the floor.

· Anodized and ground aluminium printing table, provided with belts for moving the glass to be able to handle even holed glass.

· Cycle time: 6 seconds: with maximum glass size – 800 x 1000 mm – possibility to print up to 600 glasses / h

· Recipes based printing machines and lines for quick setup & changeover.

COMPACT SERIES

Engineered for high productivity and ease of use, this machine is ideal for large production batched and the fast, precise printing of square or rectangular flat glass and rigid materials of varying sizes and shapes.

· Operator-side control panel for intuitive operation

· High-speed, high precision printing table on flat extraction for improved accessibility

· Horizontally movable printing table with full extraction for improved accessibility

· Manual loading with easy centring functionality

· Fine adjustment of the glass to screen distance

· Automatic snap off adjustment

· Precise registration on X, Y and Z axis

· Liftable printing head for an easy screen inspection and rapid cleaning

COMPACT SERIES 4C

An Advanced evolution of the compact series, the Compact 4C is designed for high precision, high volume printing on larger squared and rectangular glass. Ideal for cooktop and household appliances, including drilled glass. Its robust four column structure supports a wider printing head for enhanced performance.

· Glass size range – 150x150mm to 1300x700mm

· Fully automatic operation with belt-fed entry, pre alignment and centring

· Productivity: up to 550pcs/h for 1144x692mm glass

· Printing precision: ±0.08mm

· Quick frame extraction for cleaning without losing registration

· Compatible with E2E system for edge-to-edge printing

· Rotating printing bridge for easy squeegee and flood bar replacement

· All settings controlled via an intuitive operator panel

FLEXY SERIES

Versatile screen-printing solution for multiple glass types

Designed to handle a wide range of glass formats, this machine is ideal for both small and varied production lots, offering flexibility without compromising on precision of use.

· Suitable for diverse glass types and batch sizes

· Stainless steel magnetic table with mice perforations, featuring vacuum and blow systems for secure and effortless glass positioning

· Manual loading and unloading from the operator side

· Glass size capacity: maximum 1300x2000mm, minimum printing area 200x200mm

· All functions managed by a programmable logic controller (PLC) for reliable and automated operation

· Designed for easy and safe maintenance

OVENS AND ROBOTIC APPLICATIONS

INK CURING

Designed for high performance and reliability, this drying furnace offers advanced features across process control, safety and energy efficiency

Process control

· Fully automated temperature control system for consistent thermal processing

· Automatically regulated air inlet to ensure reliable air exchange and uniform conditions

Safety features

· Complaint with EN 1539 safety standards for processing solvent-based materials

· Robust construction designed for continuous heavy-duty operation

· Over temperature limiter with manual reset, meeting thermal protection class 2 requirements in accordance with EN 60519-2

Efficiency enhancements

· High air exchange rate to support rapid drying cycles

· High grade insulation ensures external surface temperatures to remain below 20ºC above room temperature

· Furnace commissioning includes temperature uniformity testing to optimise process performance

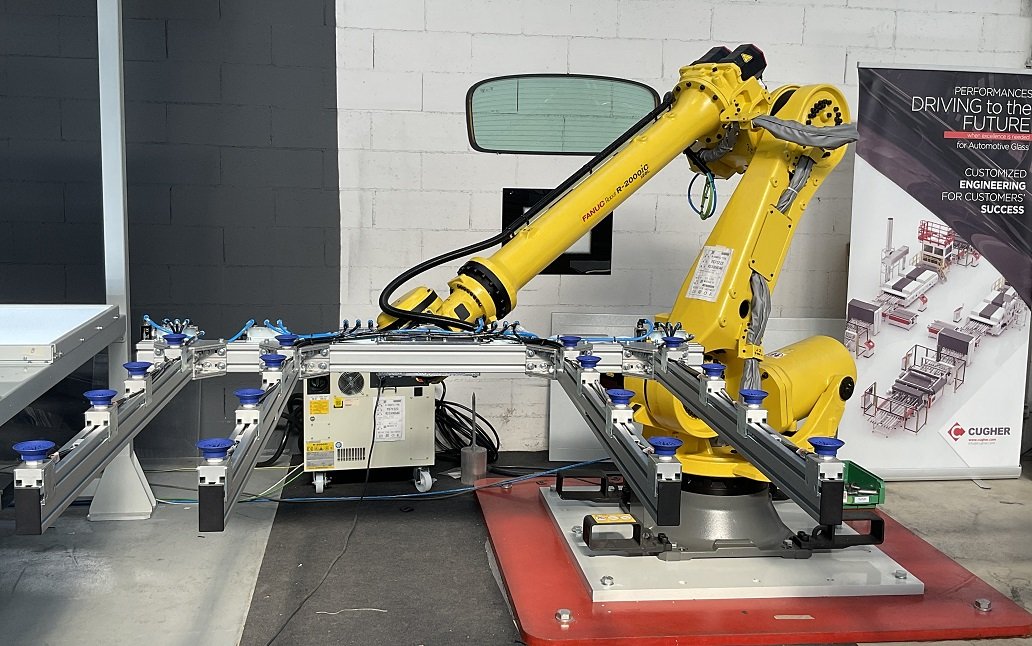

ROBOTIC APPLICATIONS

Cugher’s robotic applications, essential in modern industry and true allies of human, allow for the optimisation of the production line

· The quality of the process improves because operations are faster, more precise and uniform

· Labor costs decrease compared to manual activities

· Risks for complex and dangerous operations are reduced

· The quality of the operators works increases as they become supervisors rather than mere executors of repetitive tasks.

Cugher offers two advanced automation solutions:

Robotic Islands: automated workspaces with robot manipulators for loading, unloading and palletising. Boosting productivity and easily reconfigurable for different processes.

Robotics with vision systems: Robots integrated with vision technology for real time adjustments and precise positioning, ensuring consistent quality in complex handling tasks.

SOLAR

J SERIES

Automatic silk screen printing machine

The series J is a fully automatic silk screen printing system, comprising an entry conveyor with pre-alignment, a precision printing unit and a synchronised exit conveyor. Designed with a robust structure, it features a specially treated aluminium printing table for enhanced durability and stability.

Equipped with a belt-driven transport system and automatic centring, the Series J ensures accurate and consistent glass positioning throughout the printing process. Constructed from high quality, high efficiency materials, the machine offers reliable performance with minimal and simplified maintenance requirements.

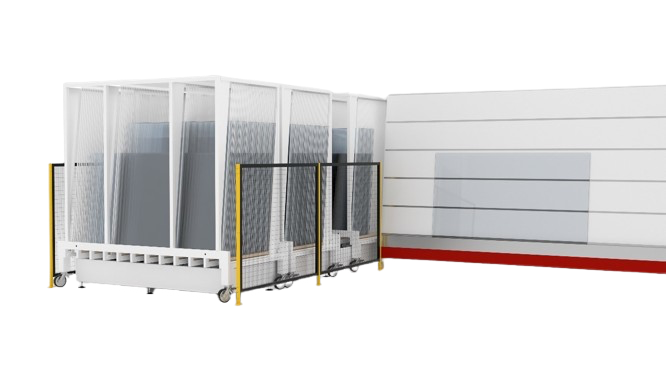

SAFETY FENCES

As required by the new European Safety Regulation, adequate safety fences must be installed to keep under control the access to the printing machine and line. The fences that have a height of 2000mm, are equipped with interlocked doors that allow the entrance into the line. The access request is made by buttons controlled by the safety access software.

Note: The installation of the safety fences is mandatory to obtain the CE Compliance Declaration for the equipment.