CUGHER

PRINT SERIES

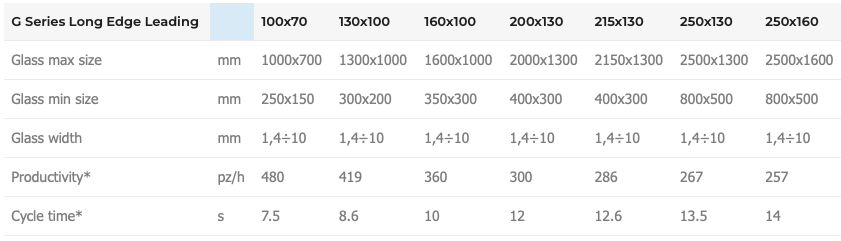

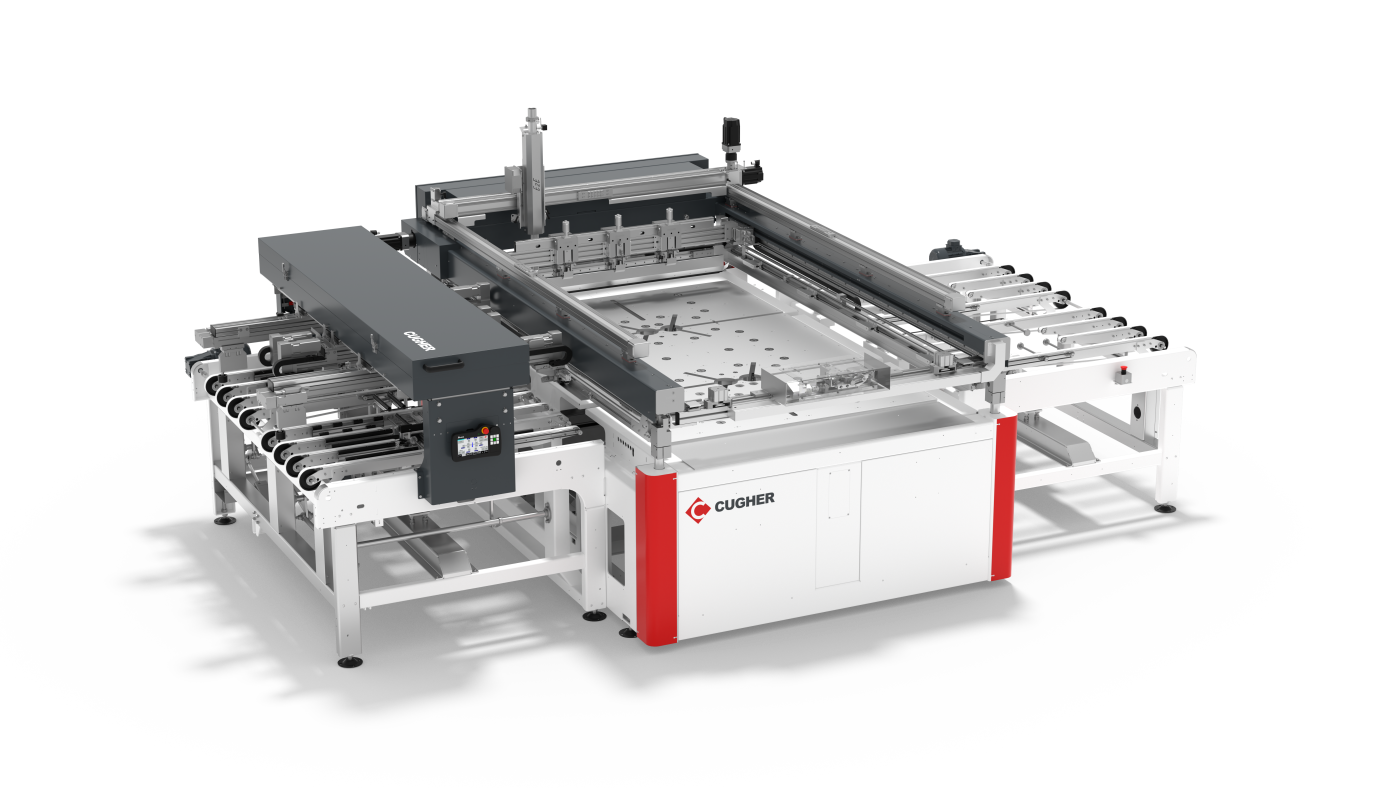

G SERIES

The G Series printing machines use a shuttle system with two independent cross-shaped holders and off-table centring to transport glass. This design maximises printing speed for small to medium sized glass. Each holder features a vacuum cup system, allowing the walking beam to collect the glass directly from the inlet conveyors centring device. This ensures precise transport and eliminates the need for additional alignment before printing.

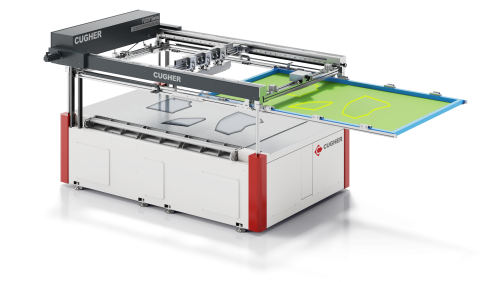

DOUBLE GLASSES SERIES

The G series DLE (Double Lite Edition) has been engineered to provide maximum flexibility within a single printing line. It allows for the simultaneous printing of two small glass panels (such as sidelights or vents) or a single large panel (such as backlite, windshield or sunroof) on one machine.

J SERIES

The Series J automatic silk Screen Printing Machine consists of an entry/pre-alignment conveyor, the main printing unit and a synchronized exit conveyor. Its robust construction features a specially treated aluminium printing table and an integrated belt transport system with auto- centring capability. Built using high quality, high-efficiency components, the Series J requires minimal land simplified maintenance.

LOGO PRINT STATION

The Logo Print Station is a specialised system comprising a booking conveyor and a logo printing unit that work together to accurately centre and print logos on the underside of the glass. Movement is driven by a pneumatic linear guide. The squeegee and flood bar speeds can be adjusted independently, while their vertical motion is controlled by dedicated cylinders. The station operated with its own integrated PLC for precise and reliable performance.

FLEXY SERIES

Designed for total flexibility, this system is ideal for printing on various glass types and is perfectly suited for small and mixed production lots. It features a stainless-steel magnetic table with micro holes, equipped with a vacuum and blow system to ensure easy and precise glass nesting. Manual loading and unloading are performed from the operator side, supporting glass dimensions up to 1300x2000mm, with a minimum printing size of 2000x200mm. All functions are managed by programmable logic controller (PLC), ensuring reliable operation, while the systems design allows for easy and safe maintenance.